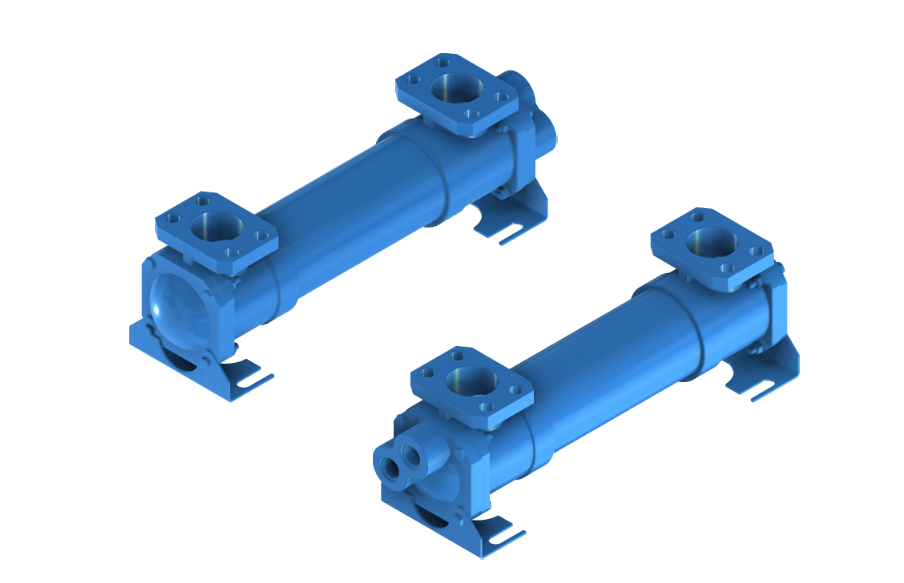

The model ST 80, result of the evolution of a standard Flovex’s exchanger, guarantees the most as thermal efficiency, compactness, combined with extreme ruggedness.

Using our patented system of elastic sealing, the ST 80 has become exceptionally safe against thermal shock and water hammering. Particular attention has been given to the issue of the corrosion due to industrial water.

The ST80 exchanger has AISI 316L Stainless Steel tube plates with high alloy hubs rolled permanently to them.

The covers waterside is made in reinforced plastic material to withstand corrosion, and water pressure. All range of models have been divided into two types according to oil flow. Type “A” for low/medium oil flow, type “B” to high oil flow.

To guarantee a high production standard, each exchanger passes a quality control and a hydraulic test before leaving our workshop.

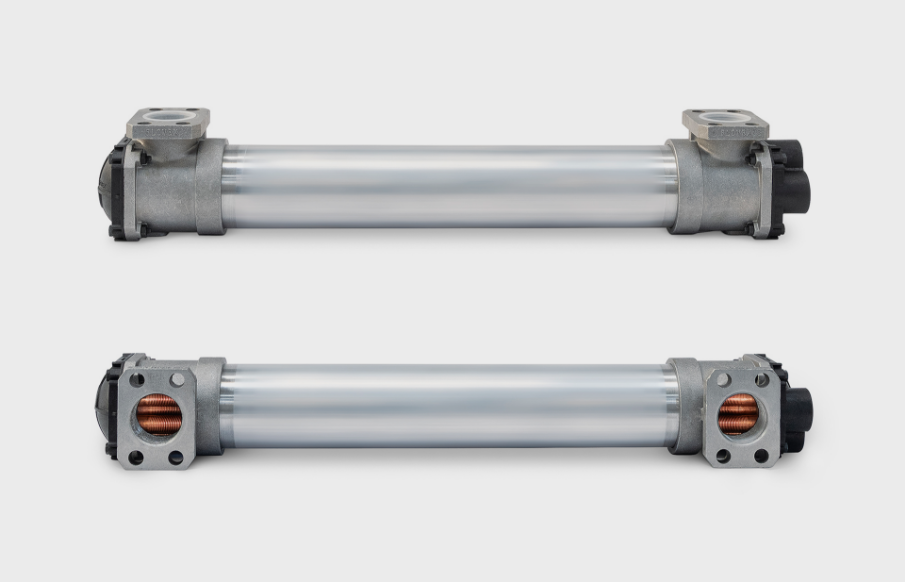

Tube bundle

High efficiency finned tubes are used, in passivated copper, expanded to the tube plates to guarantee maximum robustness even in the presence of vibrations and water hammer.

Baffles

Printed from sheet steel and perforated by punching. Both the holes and the external diameter of the deflectors allow strict and defined tolerances to guarantee maximum thermal efficiency. Both the holes and the external diameter of the deflectors allow strict and defined tolerances to guarantee maximum thermal efficiency.

Shell

Obtained by extrusion, calibrated and in light alloy, assembled by longitudinal keying to the heads; an O-ring type gasket is installed between the two elements which guarantees the hydraulic seal.

Hubs

Composed of a light moulded aluminium alloy element, which allows a connection with commercial flanges such as SAE Ø 1.½” and/or GAS thread, and of a 316 stainless steel element, which preserves the effectiveness of the pipe joint plate.

Cover

Made of plastic material, reinforced with fibreglass, and Ø 1/2″ BSP threaded steel bushes, incorporated during the printing process.

Feet

They are made of sheet steel and shaped to facilitate the installation of the cooler in different orientations.