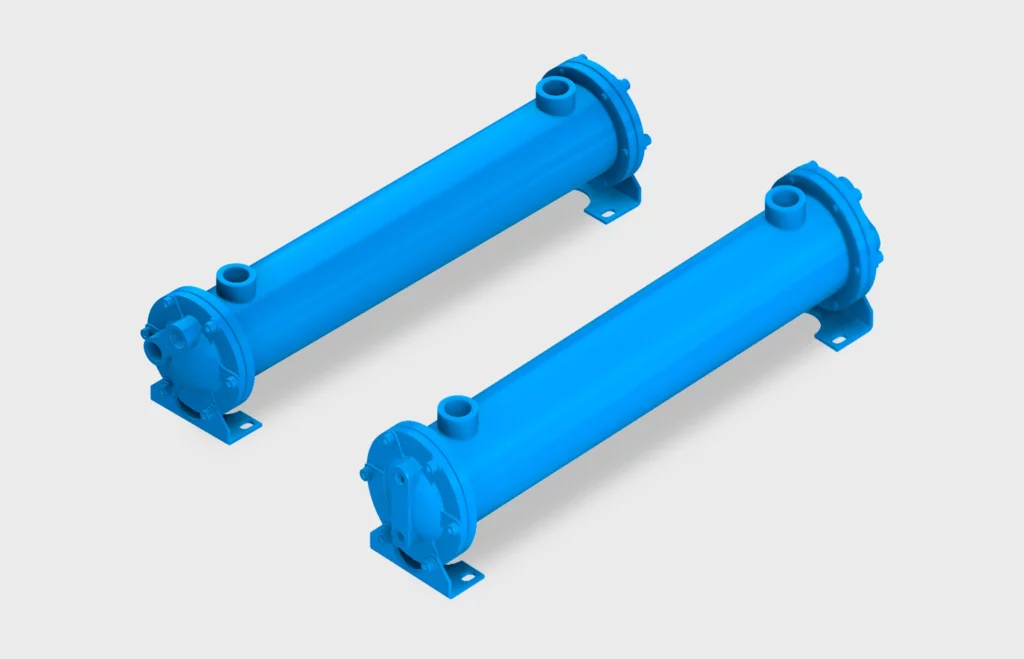

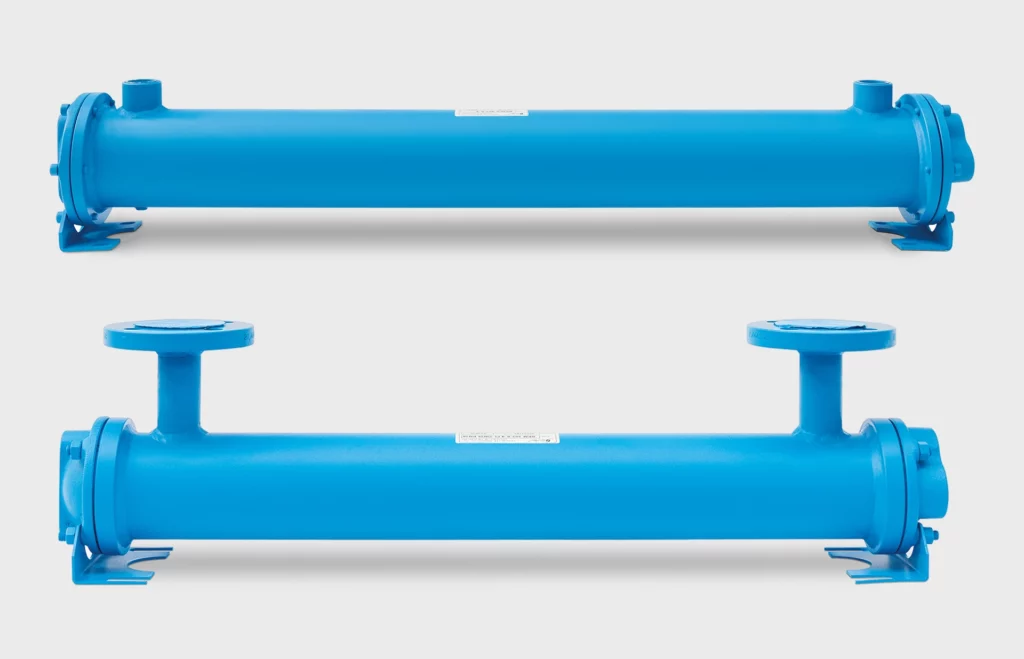

AEM/BEM series are fixed tube sheet heat exchangers, suggested for medium and heavy duties in the hydraulics, chemistry and heat recovery.

There are different layouts that can be made [A, B, L and M] to meet multiple flow needs, ensuring adequate heat exchange and low-pressure loss. This range of exchangers provides various construction both in terms of material combinations and of dimensions with surface areas that goes from 0,3m2 up to 30m2.

Tubes

The tubes used are of two different diameters:

[5/8”] available fully finned in copper and brass, or smooth in brass, iron and stainless steel

[3/8”] available smooth in stainless steel

Baffles

Printed from sheet steel and perforated by punching. Both the holes and the external diameter of the deflectors allow strict and defined tolerances to guarantee maximum thermal efficiency.

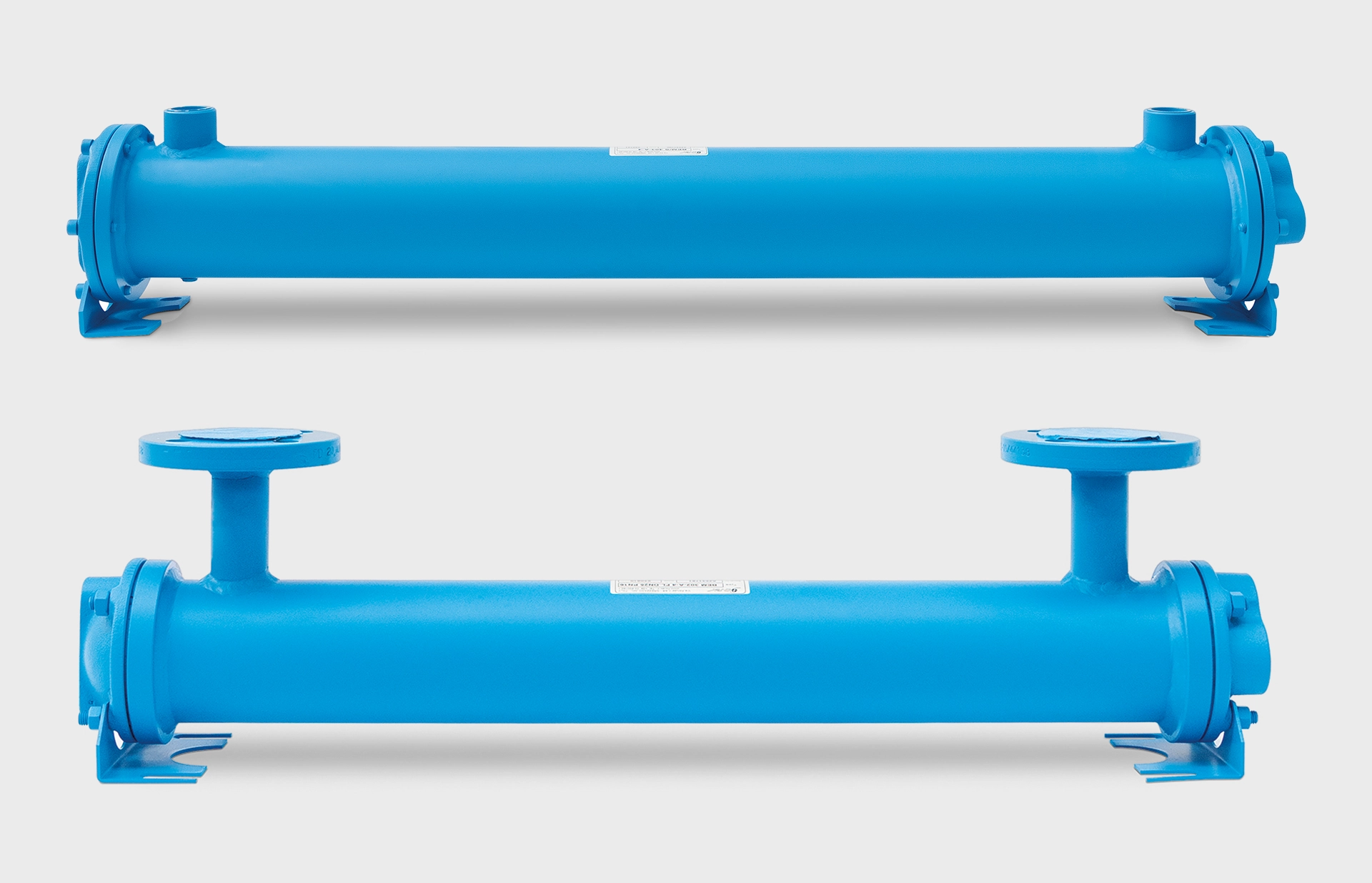

Shell

It can be realized through different combinations of materials for both the tube sheet and shell, hence completely in carbon and stainless steel or a mix of the same.

Connections are proposed with both BSP threads and with UNI – SAE – ANSI flange.

Covers

Standard executions expect cast iron covers, in 2 or 4 pass version, realized by molding or carbon/stainless steel covers made by mechanical machining and/or welding of multiple parts.

Connections are proposed with both BSP threads and with UNI – SAE – ANSI flange.