HYDROGEN SOLUTIONS

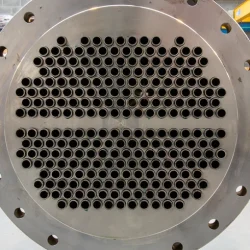

TUBE BUNDLE HEAT EXCHANGER

For high pressure hydrogen applications

In hydrogen production, compression, storage, and fuel cell systems, heat exchangers ensure optimal performance, safety, and energy efficiency.

Features

In the hydrogen industry, one of the main applications of heat exchangers concerns production processes such as methane reforming (SMR – steam methane reforming) and electrolysis.

In SMR, heat exchangers transfer heat to the reformer tubes – where the reaction takes place – thus ensuring temperature control and efficient heat transfer for the production of high-purity hydrogen.

In electrolysis, the electrochemical process in which the application of an electric current induces the splitting of a substance into simpler elements, heat exchangers are necessary for managing the temperature of the electrolyte to optimize the process.

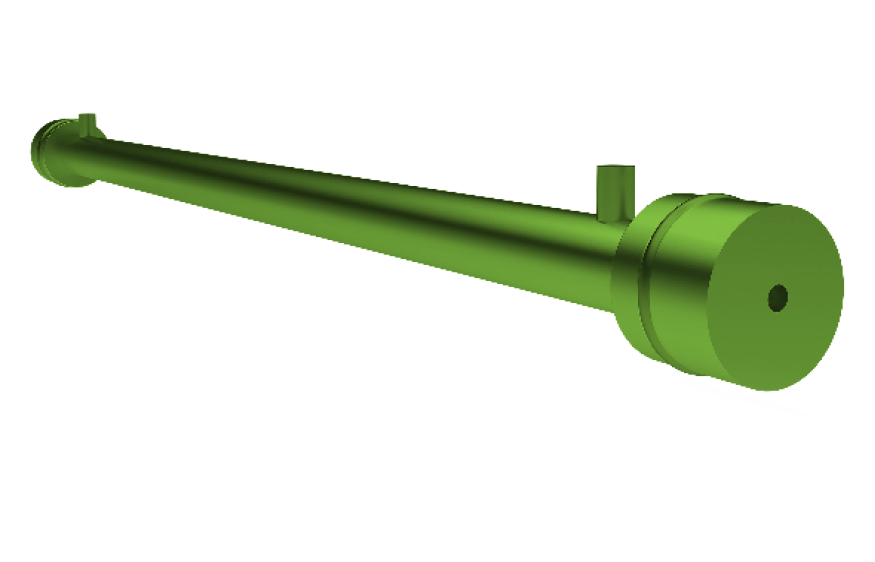

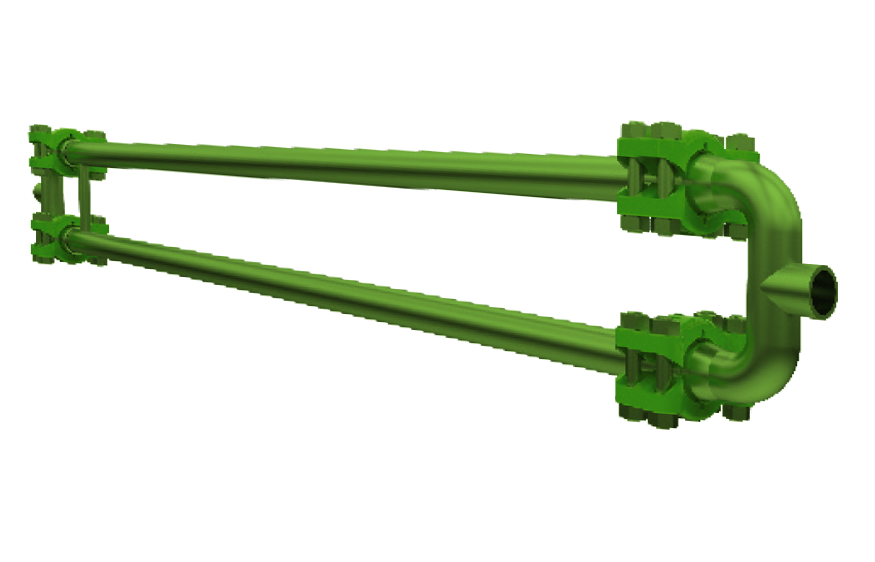

W TYPE

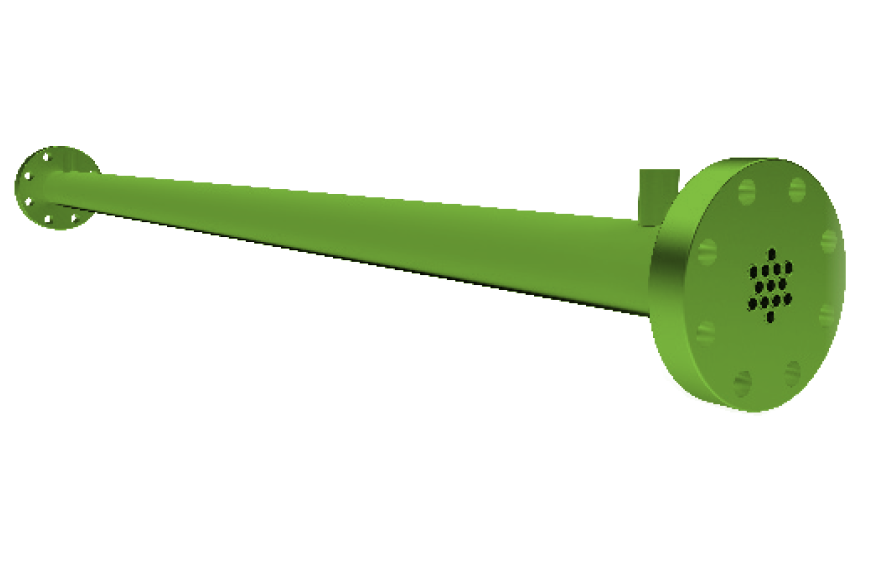

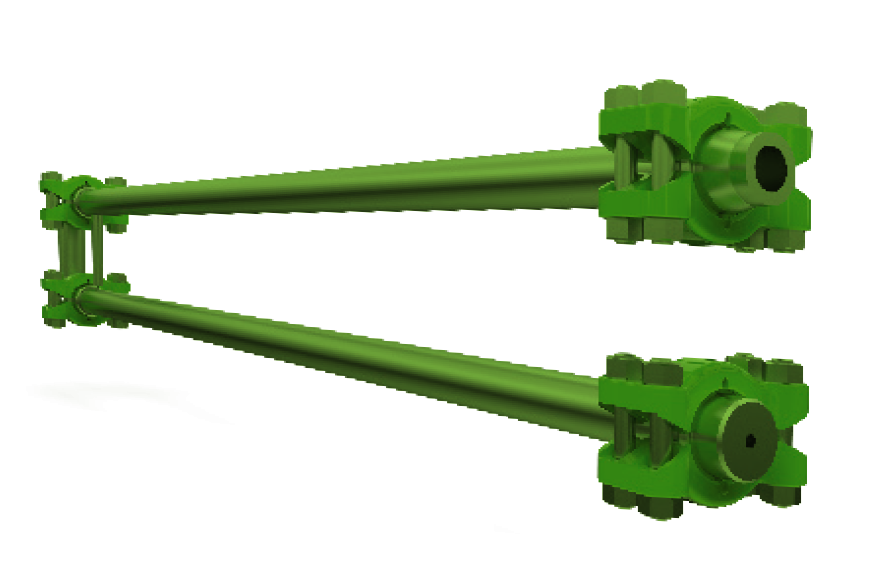

F TYPE

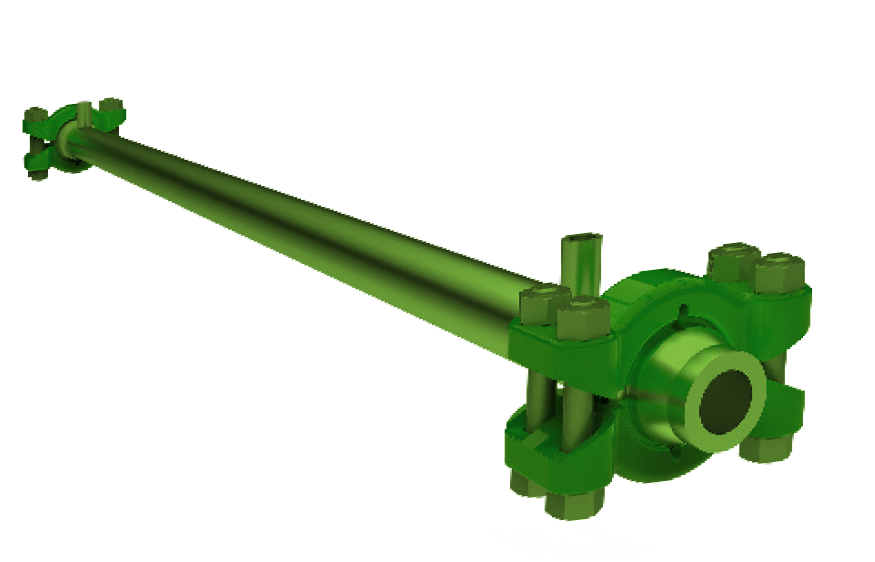

TIT - TUBE IN TUBE

C TYPE

C/P TYPE

C/S TYPE

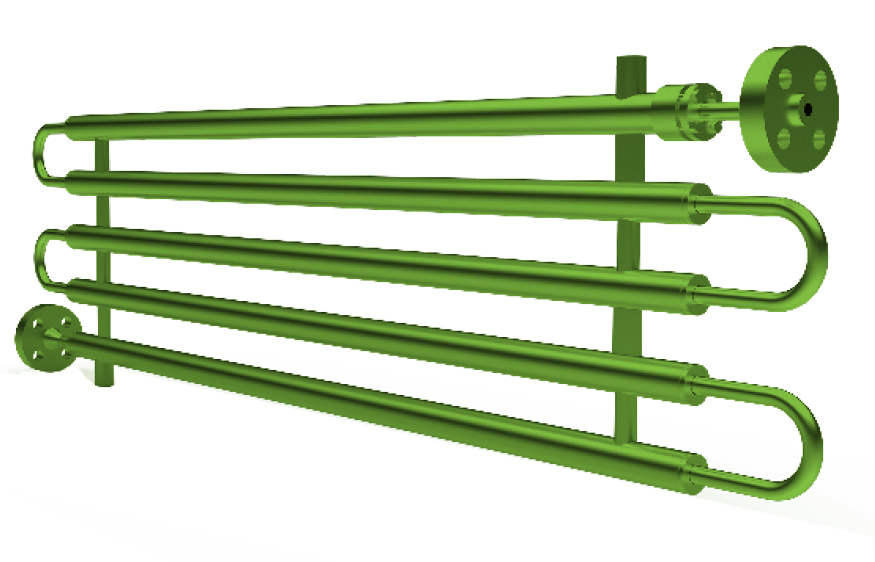

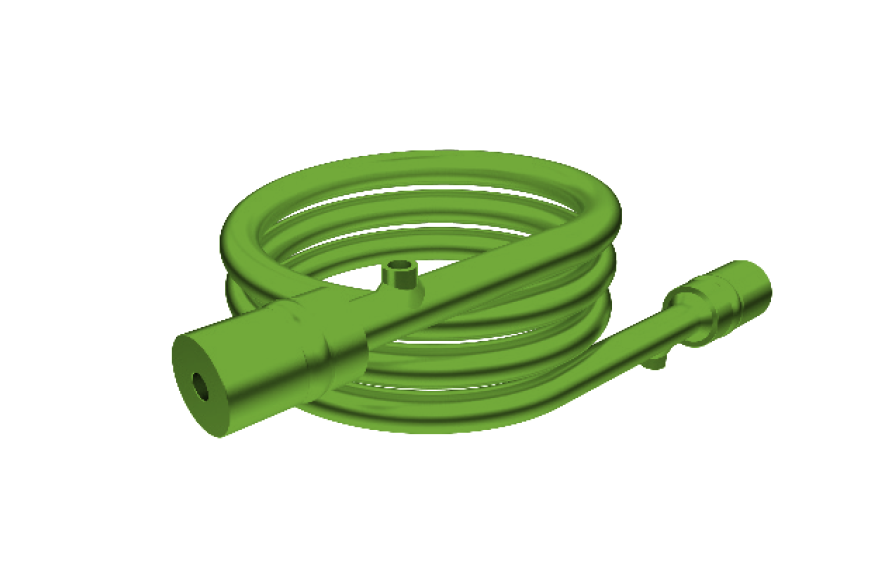

SSP - SINGLE SPIRAL TUBE

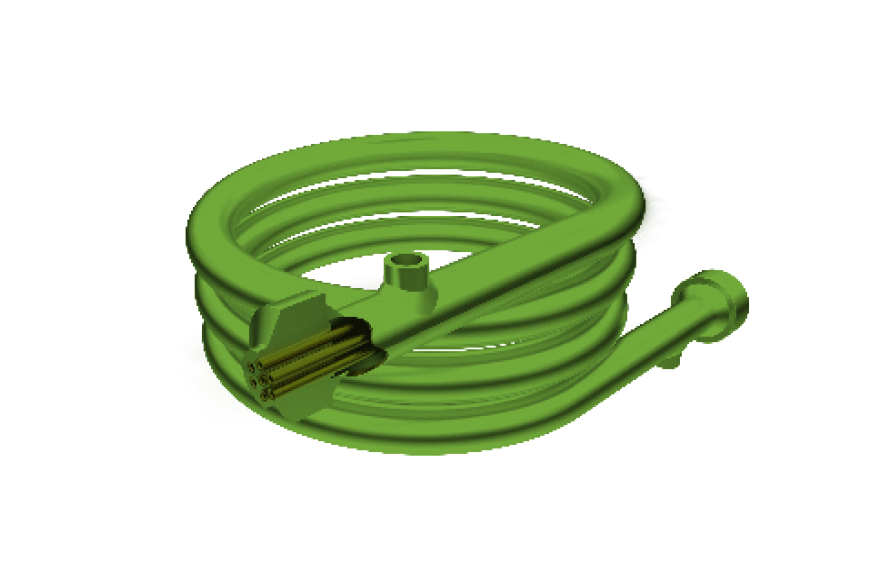

MSP - MULTI SPIRAL TUBE

CERTIFICATIONS

Flovex: international certified quality solutions

REFERENCE

Flovex has been working in the world of heat exchangers for over forty years and there are countless companies that have relied on our know-how.

PARTNERS

Flovex has been collaborating with agencies on the national and international territory for years. Find the contact closest to you here and ask for information or advice directly from our partners.